This issue in pdf Archive: |

|

|||

Digital Factories, Production Networksby László Monostori, Géza Haidegger, József Váncza and Zsolt János Viharos Today's complex manufacturing systems operate in a changing environment rife with uncertainty. The performance of manufacturing companies ultimately hinges on their ability to rapidly adapt their production to current internal and external circumstances. The Hungarian national R&D project, led by SZTAKI, combines the concepts of intelligent manufacturing systems and digital enterprises in addressing these problems. Manufacturing systems of our epoch work in a rapidly changing environment full of uncertainties. Besides internal factors such as malfunctions and breakdowns, the main external reasons for uncertainty are:

Increasing complexity is another characteristic that is evident both in production processes and systems and in enterprise structures. The concept of the digital enterprise, that is, the mapping of the important elements of enterprise processes by means of information technology tools, gives a unique way of managing the above problems. However, the optimal or nearly optimal exploitation of the huge amount of information available is impossible without the effective application of the methods and tools of artificial intelligence. In this way, systems can be developed that are expected to solve, within certain limits, unprecedented and unforeseen problems on the basis of even incomplete and imprecise information. This is the early concept of Intelligent Manufacturing Systems (IMS) by the late József Hatvany, from 1983. The project partners for 'Digital Enterprises, Production Networks', which is supported by the National Research and Development Program (NRDP) in Hungary, form a well-balanced 'academia-industry' cluster. They include GE Hungary Rt, a big manufacturing enterprise, and MT-System Ltd, an information technology SME, both of which represent industry, and the Budapest University of Technology and Economics, the Miskolc University and SZTAKI, representing academia.

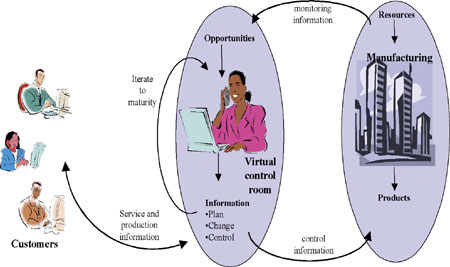

The Figure illustrates the concept of a digital, distributed enterprise representing the framework for the research. The vision of Digital Enterprises is to provide the capability to 'Manufacture in the Computer'. It incorporates a modelling and simulation environment that enables the fabrication and/or assembly of products including the associated manufacturing processes to be simulated by the computer. This capability takes into account all the variables in the production environment, from shop-floor processes to enterprise transactions. Effectively, it accommodates the visualisation of interacting production processes, process planning, scheduling, assembly planning, and logistics from the resource to the enterprise level. The main characteristics of the project correspond to the above main tendencies:

The project has the following - partly overlapping - main directions, which will be treated in a comprehensive way:

This national R&D project aims to make all the important production-related information available and manageable in a controlled, user-dependent way by the efficient application of information and communication technologies. The development and application of intelligent decision support systems will help enterprises to cope with the problems of uncertainty and complexity, increase their efficiency, join in production networks and to improve the scope and quality of their customer relationship management. Please contact: |

|||