by Zsolt János Viharos and László Monostori

Reliable process models are extremely important in different fields of computer integrated manufacturing. One of the main goals of the project is to generate multipurpose models that are applicable for a set of assignments and can satisfy the various accuracy requirements at the same time. As to the application phase, novel techniques are needed to find the unknown (input) parameters of the model in certain situations. The modelling and optimisation of process chains are of special importance. These issues are treated and solutions for them are given in a Ph.D. work completed these days at SZTAKI.

Difficulties in modelling manufacturing processes are manifold considering the great number of different machining operations, the multidimensional, nonlinear, stochastic nature of machining, partially known relations between parameters, lack of reliable data, etc. A number of reasons necessitate the required models: design, optimisation, control and simulation of processes and design of equipment. On the base of the applied knowledge, fundamental, heuristic and empirical models can be distinguished.

Artificial neural networks (ANNs) are general, multivariable, nonlinear estimators. This soft computing technique can offer viable solutions especially for problems where abilities for real-time functioning, uncertainty handling, sensor integration, and learning are essential features. Successful applications in manufacturing were reported on in the literature. The assignments to be performed determined the I/O configurations of the models, ie which parameters are to be considered as inputs and which ones as outputs. This predetermination, however, results in models which do not necessarily produce the best mapping between the considered quantities.

A novel approach for generating multipurpose models of machining operations has been developed which combines machine learning and search techniques. Because of the general nature of the multipurpose models, almost in every application, only some of the input parameters are known, and the task is to determine the unknown parameters while satisfying some constraints. For this purpose, a simulated annealing search technique has been developed.

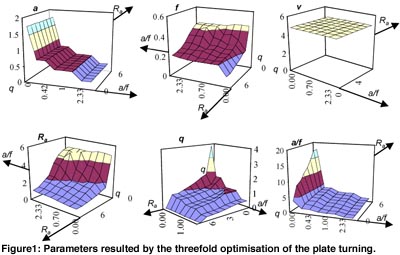

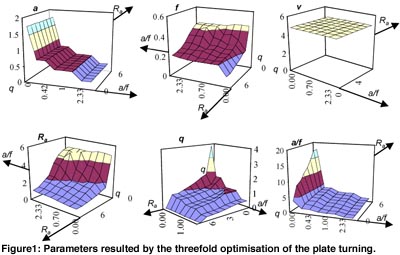

Figure 1 illustrates the application of the developed software package ProcessManager for the threefold optimisation of the viewpoints of the customer (minimisation of the surface roughness), the owner of the company (profit/productivity maximisation) and the production engineer (maximisation of process stability through the a/f ratio). Ratios of the weighting factors of the three variables to be optimised are represented along the axes.

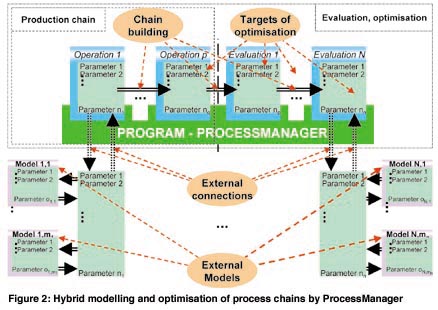

Special emphasis was laid on the optimisation of manufacturing processes and process chains. A block-oriented framework for hybrid modelling and optimisation of coupled processes has been developed where the individual process models can be of different types, ie having the form of ANNs, expert systems or equations (see Figure 2).

The ProcessManager incorporates:

It is expected that the developed package would be a valuable tool for the modelling, monitoring and optimisation of manufacturing processes and process chains. Taking the globalisation issues and the increasing role of virtual enterprises into account, the distributed version of the system is expected to show further benefits. This project is partially supported by the Hungarian Scientific Research Fund, Grant Nos. F026326 and T026486.

Please contact:

László Monostori - SZTAKI

Tel. +36 1 209 6990

E-mail: laszlo.monostori@sztaki.hu